Excellent and Reliable TERS Cantilever-type Probes

The main advantages:

– Enhancement factors: 100x and more

– Lateral resolution in TERS: down to 10nm

– High speed TERS mapping

– Top-down illumination configuration (opaque samples)

– Based on commercial AFM cantilevers

VIT_P series (contact, non-contact), multiple AFM modes, excellent imaging performance.

Fig. 1 Typical Raman signal enhancement (>100x) of NT-MDT Spectrum Instruments TERS AFM probe.

|

|

|

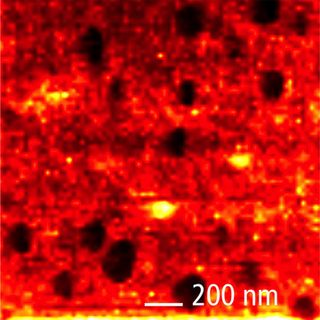

Fig. 2 High resolution TERS map. Resolution: ~20 nm.

Sample: BCB thin molecular layer on Au substrate.

|

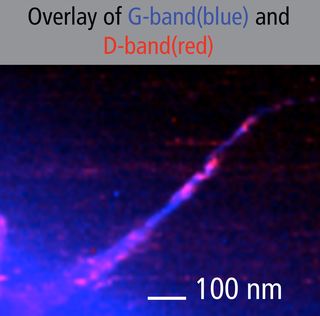

Fig. 3 High resolution TERS map of carbon nanotubes on Au substrate. Resolution: ~10 nm

|

TERS (nano-Raman) imaging by NT-MDT S I AFM-Raman instrument.

NT-MDT Spectrum Instruments develops and supplies unique instrumentation for AFM integration with various optical microscopy and spectroscopy techniques. NT-MDT Spectrum Instruments was the first to introduce an integrated AFM-Raman instrument in 1998 and is now the leading developer and supplier of such instruments worldwide.

NT-MDT Spectrum Instruments AFM-Raman instrument has been successfully used for TERS (nano-Raman) mapping of various objects with spatial resolution reaching 10 nm: graphene and other carbon nanomaterials, polymers, thin molecular layers (including monolayers), semiconductor nanostructures, lipid membranes, various protein structures, DNA molecules etc. References to corresponding publications can be found at

www.ntmdt.com/afm-raman .

TERS probe challenge.

While the AFM-Raman instrumentation has been developing relatively fast, TERS probes have always remained the main limiting factor for nano-Raman to become a routine characterization technique.

The main challenges are:

- manufacturing reproducible probes with high enhancement factors and high resolution imaging capabilities;

- probe lifetime;

- probe ease of use;

- probe mass production not involving complicated and poorly reproducible manual procedures.

TERS probes originally used in scientific publications were usually etched metal wires - attached to tuning fork or working in STM (tunneling) regime. Preparation of such probes requires elaborate manual operations; probes are typically not very reproducible. Another approach to TERS probe preparation utilizes focused ion beam to manufacture special structure on the tip end. This approach is very resource consuming and also lacks reproducibility. Different metal coatings of AFM cantilevers have been reported recently – with different degrees of enhancements and reproducibility.

Reproducible TERS probes from NT-MDT S I.

As a result of comprehensive research performed together with NT-MDT Spectrum Instruments customers and partners, NT-MDT Spectrum Instruments is now able to offer to its AFM-Raman customers mass produced reproducible cantilever-type TERS probes. The probes are prepared based on so-called “Top Visual” AFM Si cantilevers (Fig. 2). Special proprietary probe preparation and TERS metal coating are applied.

AFM probes can have different stiffness and can be optimized for contact and non-contact regimes.

Protruding “nose-type” shape of the probes allows the Raman laser light to be focused on the probe apex from the top: for use with non-transparent samples.

The probes provide guaranteed TERS performance on a test sample (organic molecules on Au substrate):

- Enhancement factor >50x (Tip IN vs. Tip. OUT) for ~70% of probes. Typical enhancement factor : > 100x. Some probes reach >500x enhancement.

- TERS (nano-Raman mapping). ~20-70 nm resolution. >50% of probes.

- Remarkable lifetime without considerable enhancement degradation

The TERS AFM probes also feature excellent AFM performance in contact and non-contact regimes since they are prepared based on standard Si AFM cantilevers produced by mass technology. All advanced AFM modes (electrical, magnetic, nanomechanical etc.) are available with NT-MDT Spectrum Instruments TERS probes. High resonance quality factors (for non-contact probes) allow excellent force sensitivity and guarantee long tip lifetime during measurements.

STM TERS probes (electrochemically etched metal wires) and TERS probes attached to tuning fork are also available.

The NT-MDT Spectrum Instruments TERS probes reach their highest potential with the unique AFM-Raman instrument from NT-MDT SI: specifically designed for TERS research.

Probes are only supplied to be used with NT-MDT-SI instrumentation.